Processkrav til LVDS-seleenheder

klik : 51

Opdatér tid : 2022-08-17

This browser does not support the video element.

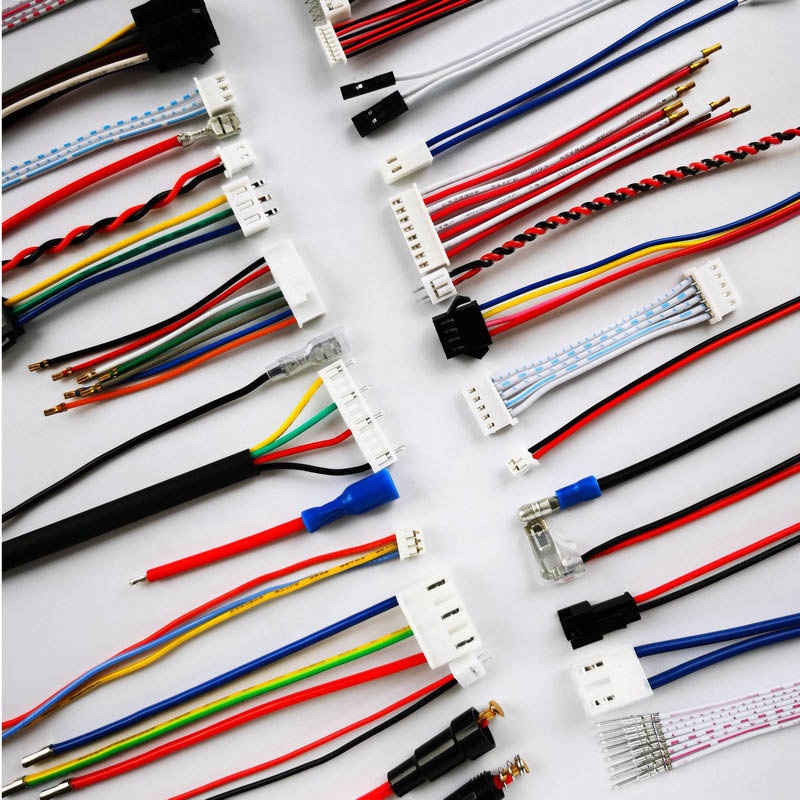

After the harness is processed and assembled, all harnesses should be parallel and cannot be moved; However, the wire rope or wire harness shall not jam the wire.

When inserting pin or welding, the core wires cannot be wound together, but they cannot be too tight.During wiring, the terminals, housing, D-sub, IDC, Conn of each sub part number must be consistent with the marks on the positioning board.

The wire of each sub item number must be arranged according to the route on the positioning plate.

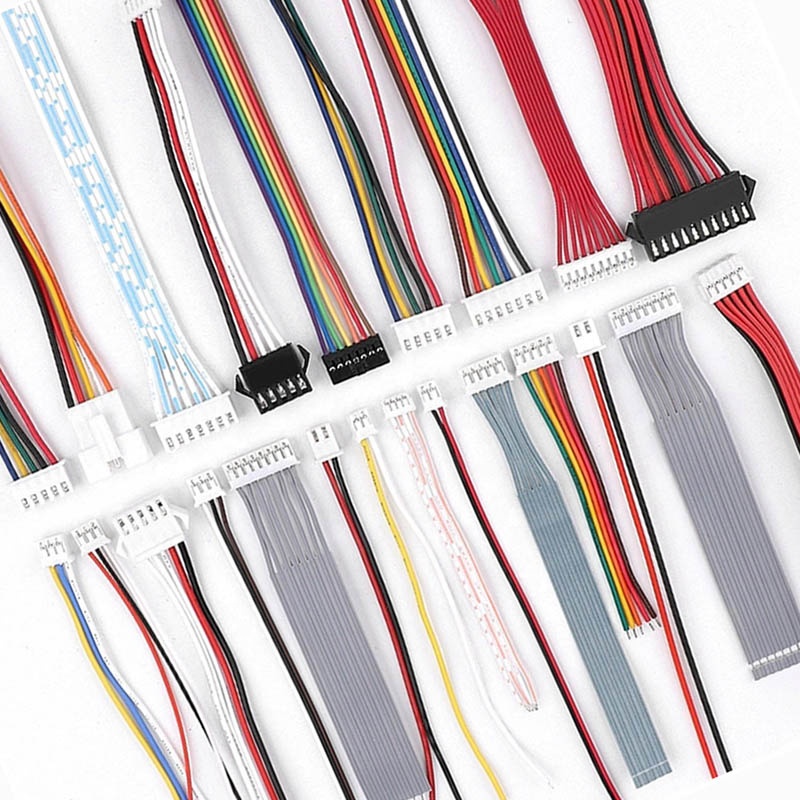

When binding, the rope should move vertically from the lower side of the binding ring.

The wire harness should be tightened, and the tail should not exceed 1mm

When binding, the distance between the two binding rings is about 25mm, and each rope should be tied to the end with a tail of about 10mm.

Each rope should be tied at the beginning and end.

Do not loop or wind the rope when binding. The connector cannot be stuck on the locating pin, and the rope should be pulled hard. The wire head of the rope should be fixed on the locating pin, and then the wire should be tied (otherwise, it is easy to cause the terminal to break the core wire or the terminal to fall off.)